Description

Organizations working with Engineered and Manufactured systems have decades of pioneering experience in the design, implementation, and operation of instrumented products. Aerospace, automotive, maritime, and building systems are often highly laden with sensors that observe real-time performance of these product systems as they operate. Remote observers may communicate and even control these systems from afar. Over the lifetime of these systems – airplanes, cars, buildings, and ships – data on the performance across a large set of diverse, released product systems reveals much about the gap between as-designed, as-built, and as-operated actual systems.

Therefore, the IoT trend is not new to our community, yet the scale, reduced latency and cost, heterogeneity, and especially interconnectivity of these systems across economic and social infrastructures has been dramatic. Most significantly, rather than viewing these data sets product by product, we need consider the performance of instrumented products in the interplay amongst many systems and especially with people. To take advantage of these opportunities, not only must the design of our engineered systems advance, but also how we engineer will be transformed.

In the IEEE World Forum on IoT Industry Track we will discuss recent cases and emerging research on the application of IoT in industry. We will discuss the transformation of industrial organizations to become aware, explore, and rapidly respond to new data science capabilities. The important concurrent trend in model-based or digital engineering along with IoT will also be considered. Finally, we will bring in the discussion of instrumentation of teamwork: the capability to see and predict in real time the performance of human teams as they work, coordinate, work, make mistakes, adjust and learn (or not.) Speakers and papers from engineering and manufacturing in aerospace, automotive, maritime, and building infrastructure are welcome.

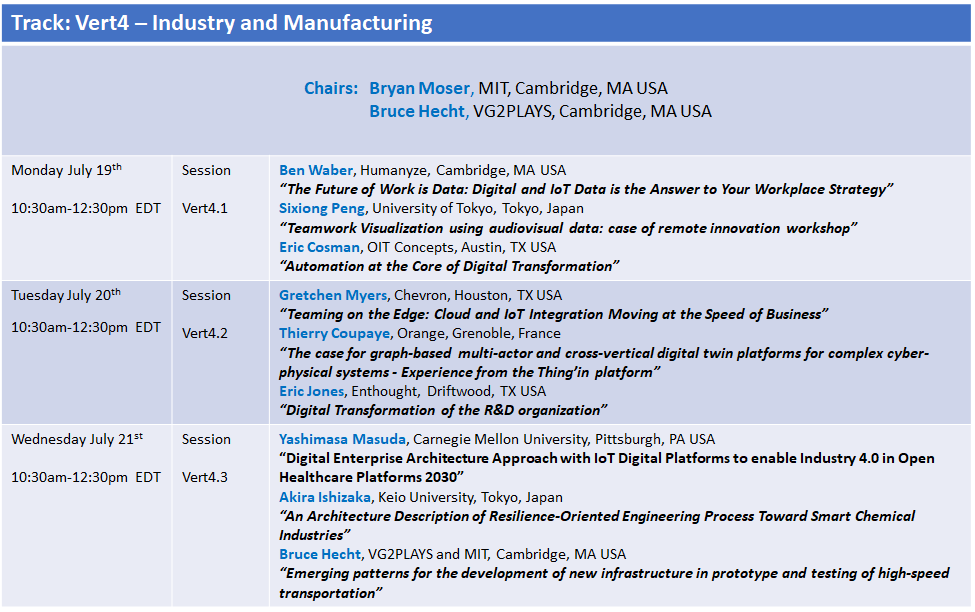

Track Co-Chairs

Bryan Moser, Academic Director, System Dynamics & Management, MIT, Cambridge, MA USA

Dr. Bryan Moser is Sr. Lecturer and Academic Director of System Design & Management (SDM) at MIT, and a Project Associate Professor at the University of Tokyo, where he directs the Global Teamwork Lab (GTL. Prior to returning to MIT in 2014, he worked for 25 years in industry; as a research engineer at the Basic Science Lab (A.I.) of Nissan Motor Company, as a Sr. Research Scientist at United Technologies Corporation, and as founder and President of Global Project Design, a firm pioneering software and methods for model-based project management. Moser focuses on engineering teamwork for complex systems problems and use of model-based methods to improve performance of diverse teams. Moser received a Bachelor in Computer Science and Engineering in 1987 and a Master of Science in Technology and Policy from the Massachusetts Institute of Technology in 1989. His doctorate in 2012 is from the University of Tokyo, Graduate School of Frontier Sciences.

Dr. Bryan Moser is Sr. Lecturer and Academic Director of System Design & Management (SDM) at MIT, and a Project Associate Professor at the University of Tokyo, where he directs the Global Teamwork Lab (GTL. Prior to returning to MIT in 2014, he worked for 25 years in industry; as a research engineer at the Basic Science Lab (A.I.) of Nissan Motor Company, as a Sr. Research Scientist at United Technologies Corporation, and as founder and President of Global Project Design, a firm pioneering software and methods for model-based project management. Moser focuses on engineering teamwork for complex systems problems and use of model-based methods to improve performance of diverse teams. Moser received a Bachelor in Computer Science and Engineering in 1987 and a Master of Science in Technology and Policy from the Massachusetts Institute of Technology in 1989. His doctorate in 2012 is from the University of Tokyo, Graduate School of Frontier Sciences.

Bruce Hecht, CEO and Chief Technology Officer VG2PLAYSystem Design & Management Fellow, MIT, Cambridge, MA

Bruce Hecht is CEO/CTO of VG2PLAY, advancing virtual games design for learning, based at the Cambridge Innovation Center, Cambridge, MA, USA. He has over 25 years’ experience in new products and new technology introduction at Analog Devices Inc., including twice receiving the ADI “Ahead of What’s Possible” award for MEMS and high-speed design, and the ADAS1000 recognized by EDN – Best Electronic Design in Medical Electronics (2011). He has organized professional and technical conferences in North America, Europe, Asia, and India and has served as design challenge mentor for events including MIT Hacking Medicine and the Yale-New Haven Hospital / CBIT. Designing for future challenges was highlighted at the workshop “Learning Future Workforce” for the 2020 IEEE Integrated STEM Education Conference. Bruce holds the B.A.Sc. an M.A.Sc. in Electrical Engineering from the University of Waterloo, Ontario, Canada (1992 and 1994) and is currently an SDM Fellow at MIT. He holds 6 U.S. Patents and is an ASQ 6σ Black Belt. Bruce is the SSCS Representative for Biometrics Council, the VP-Elect, Finance for IEEE EMBS, and the Chair of the IEEE SA Telehealth Industry Connections program. You may find Bruce at Soundcloud or your favorite podcast platform for the Array Café, a “life-in-tech” podcast he co-produces with IEEE global colleagues.

Bruce Hecht is CEO/CTO of VG2PLAY, advancing virtual games design for learning, based at the Cambridge Innovation Center, Cambridge, MA, USA. He has over 25 years’ experience in new products and new technology introduction at Analog Devices Inc., including twice receiving the ADI “Ahead of What’s Possible” award for MEMS and high-speed design, and the ADAS1000 recognized by EDN – Best Electronic Design in Medical Electronics (2011). He has organized professional and technical conferences in North America, Europe, Asia, and India and has served as design challenge mentor for events including MIT Hacking Medicine and the Yale-New Haven Hospital / CBIT. Designing for future challenges was highlighted at the workshop “Learning Future Workforce” for the 2020 IEEE Integrated STEM Education Conference. Bruce holds the B.A.Sc. an M.A.Sc. in Electrical Engineering from the University of Waterloo, Ontario, Canada (1992 and 1994) and is currently an SDM Fellow at MIT. He holds 6 U.S. Patents and is an ASQ 6σ Black Belt. Bruce is the SSCS Representative for Biometrics Council, the VP-Elect, Finance for IEEE EMBS, and the Chair of the IEEE SA Telehealth Industry Connections program. You may find Bruce at Soundcloud or your favorite podcast platform for the Array Café, a “life-in-tech” podcast he co-produces with IEEE global colleagues.

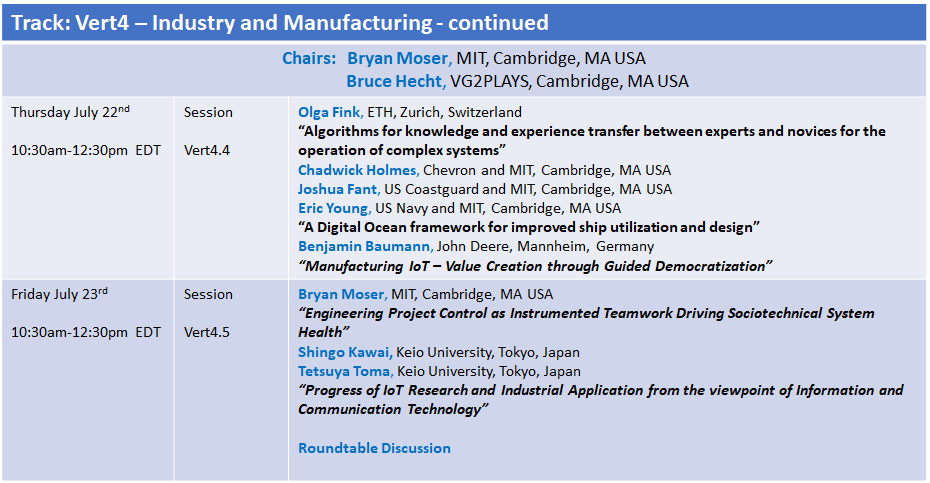

Speakers

Ben Waber, President and co-founder of Humanyze

Ben Waber is the president and co-founder of Humanyze, a workplace analytics company. He is also a visiting scientist at the MIT Media Lab, where he received his PhD, and previously worked as a senior researcher at Harvard Business School. Waber’s work has been featured in major media outlets such as HBR, CNBC, and NPR. His book, People Analytics, was published by the Financial Times Press in 2013.

Ben Waber is the president and co-founder of Humanyze, a workplace analytics company. He is also a visiting scientist at the MIT Media Lab, where he received his PhD, and previously worked as a senior researcher at Harvard Business School. Waber’s work has been featured in major media outlets such as HBR, CNBC, and NPR. His book, People Analytics, was published by the Financial Times Press in 2013.

Title: The Future of Work is Data: Digital and IoT Data is the Answer to Your Workplace Strategy

Abstract: “In the last few years data around the way we work has grown exponentially. With the impacts of the sudden shift to remote work in 2020 and the needs of employees changing, the future of work needs to rely on data to make more informed decisions to better the work-life of employees and positively impact business outcomes. As companies explore their post-pandemic strategies and decide on a path that better suits their needs a combination of digital and IoT data will help evaluate the impacts of those decisions. In this conversation we will explore the role of combining digital and IoT data in making informed decisions about hybrid and full return to the office strategies. In this talk you will learn:· The role of combined digital and IoT data in planning a post-pandemic strategies· How companies leverage IoT data in their people decisions· The importance of continuous measurement”

Shingo Kawai, System Design and Management , Keio University

Shingo Kawai, Researcher, SDM Research Institute, Graduate School of System Design and Management, Keio UniversityDr. Kawai has over 29 years’ experience as a research engineer in optical communications. Since joining Keio University in 2015, his activity has expanded in tackling sociotechnical problems by using ICT technologies. His research interest includes optical communications, technology strategy in telecommunications industries, innovation dynamics, and application of ICT technologies to future smart cities/societies.He received a B. S. in Physics and a Ph. D. in Electric and Electrical Engineering from Tokyo Institute of Technology in 1992 and 2007, and a M. S. in Engineering and Management from Massachusetts Institute of Technology in 2014. He is an international standardization member of fiber optic communications systems and sub-systems working group at IEC (International Electrotechnical Commission), and a member of the editorial board at Laser Society of Japan.

Shingo Kawai, Researcher, SDM Research Institute, Graduate School of System Design and Management, Keio UniversityDr. Kawai has over 29 years’ experience as a research engineer in optical communications. Since joining Keio University in 2015, his activity has expanded in tackling sociotechnical problems by using ICT technologies. His research interest includes optical communications, technology strategy in telecommunications industries, innovation dynamics, and application of ICT technologies to future smart cities/societies.He received a B. S. in Physics and a Ph. D. in Electric and Electrical Engineering from Tokyo Institute of Technology in 1992 and 2007, and a M. S. in Engineering and Management from Massachusetts Institute of Technology in 2014. He is an international standardization member of fiber optic communications systems and sub-systems working group at IEC (International Electrotechnical Commission), and a member of the editorial board at Laser Society of Japan.

Tetsuya Toma, System Design and Management , Keio University

Tetsuya Toma, Professor, Graduate School of System Design and Management, Keio University, and Deputy Director, Keio Photonics Research Institute. With industry work experience at 3M Company as a product development specialist in both Japan and U.S. for 20 years, Dr. Toma became a professor of Graduate School of System Design and Management in Keio University in 2008. He received Doctor of Philosophy (Ph.D.) in System Design and Management from Keio University and Project Management Professional (PMP) from Project Management Institute (PMI). Dr. Toma is a past director of PMI Japan Chapter (2010-2017) and a current director of PMI Global Accreditation Center for Project Management Education Programs (GAC) since 2020. As a deputy director of Keio Photonics Research Institute (KPRI), he leads a team developing an innovative optical communication system for next generation high-definition video transmission system without latency using plastic optical fibers. One of the team’s novel inventions was an optical connector using a ball-point pen manufacturing technology that greatly reduced cost. At the graduate school of SDM, Dr. Toma has led “Communication Design Laboratory” and taught Project Management and its related courses for more than 10 years. His research and education interests include program/project management, communication design for communities such as medical/health care, education, and local resource utilization.

Title: Progress of IoT Research and Industrial Application from the viewpoint of Information and Communication Technology

Abstract: “Accelerated by high-speed/low-latency/multi-connected 5G mobile communication technologies, the leading part of communication has shifted from humans to Internet of Things (IoT) terminals. Digital transformation in various industries is expanding so that everything will be digitized and connected through communication networks in the near future. Applications and demonstrations of IoT are especially active in areas of electric powers, ship navigations, aeronautical engineering, manufacturing. For such technological evolution, services/applications technology such as digitization in the real world as well as large capacity and low latency communication technology are indispensable.In the first half of this presentation, we take up digital twin computing as a key technology that links the real world to the virtual world, and review potential applications and use cases in some industries. Several emerging technologies that construct digital virtual models of physical objects and networks to simulate their behaviors in environments are discussed. Technical issues, such as the need to increase traffic to realize digital twins and the need for security measures due to the vulnerabilities contained in IoT networks, are discussed.In the second half, we introduce the current trends of large capacity and reliable optical transport technology that supports the backbone of 5G networks. They include cutting-edge digital coherent transmission and space division multiplexing in order to expand transmission capacity as well as maintenance-free network technology that enables monitoring and proactive maintenance of optical networks by employing machine learning. We also try to envision future technological directions.”

Eric Jones, Enthought

Widely known as one of the founding fathers of Python’s scientific community, Eric drives business growth through digital transformation. For 20 years, he has been an innovator in applying machine learning, image processing, 3D visualization, and parallel computing to elegantly solve the most complex business problems. Prior to founding Enthought in 2001, Eric focused on numerical electromagnetic and genetic optimization in the department of electrical engineering at Duke University. He holds both a Ph.D. and M.S. in electrical engineering from Duke University and a B.S.E. in mechanical engineering from Baylor University.

Widely known as one of the founding fathers of Python’s scientific community, Eric drives business growth through digital transformation. For 20 years, he has been an innovator in applying machine learning, image processing, 3D visualization, and parallel computing to elegantly solve the most complex business problems. Prior to founding Enthought in 2001, Eric focused on numerical electromagnetic and genetic optimization in the department of electrical engineering at Duke University. He holds both a Ph.D. and M.S. in electrical engineering from Duke University and a B.S.E. in mechanical engineering from Baylor University.

Title: Digital Transformation of the R&D organization

Abstract: “Advances in digital technologies such as AI, image processing, and simulation offer tantalizing opportunities to accelerate R&D across a wide range of industries. The promise of superior products with a shorter time to market is real, and companies able to reliably and repeatedly couple digital tools into their R&D engine will have remarkable advantages in the decades to come. Often the perceived path to transformation revolves around adoption of cloud infrastructure, data lakes, and the latest algorithms. While these are often outcomes of a digital transformation, they are not the means of achieving it. True transformation comes from intentional emphasis on accelerating the R&D process itself. This is often a cultural shift within organizations that track product delivery timelines much more closely than the underlying process that creates them.Corporations have built their successful strategies on human centric processes that have evolved (and ossified) over decades. Digital technologies instead flourish with digital centric processes that emphasize, among other things, efficient repeatability and thorough machine readable data capture often missing from historic approaches. Moving from human centric to digital centric processes is a fundamental requirement for digital transformation. It requires a new mentality as well as new skills for both the management and scientific team.In this talk, we will examine approaches for shifting an R&D organization from human centric to digitally centric processes and strategies for dealing with the inevitable roadblocks that arise along the way.”

Thierry Coupaye, Orange

Thierry Coupaye is head of research on Internet of Things (IoT) inside Orange, and Orange Expert on Future Network. He completed his PhD in Computer Science in 1996 and his habilitation (HDR) in 2013 from the University of Grenoble (France). He had several research and teaching positions at Grenoble University, European Bioinformatics Institute and Lion Biosciences (Cambridge, U.K.) and Dassault Systems. He joined Orange in 2000 where he had several research expert, project manager, project and program director positions in the area of distributed systems architecture, autonomics, cloud/fog/edge computing and networking. He has been an initiator of Orange activities in autonomic computing, server and network virtualization, cloud/fog/edge computing and networking, digital twins. He is the author of more than 75 refereed articles and has participated in multiple program and organization committees of international conferences in these areas. He has been involved in several collaborative projects and is a regular expert for French (ANR, Inria, Telecom Sud Paris, IMT Atlantique) and European research agencies. Thierry is member of the steering committee of the Inria and Orange joint laboratory IOLab, member of the board of the Edge Intelligence professorship inside the Multidisciplinary Institute in Artificial Intelligence (MIAI), and currently contributes to the Digital Twin Working Group of the French Alliance for the Industry of the Future (AIF). Thierry is one of the creators of the Fractal software component model and more recently the Thing’in digital twin platform. His current research interests include Digital Twins and Edge Intelligence (AI@Edge) for Cyber-Physical Systems.

Thierry Coupaye is head of research on Internet of Things (IoT) inside Orange, and Orange Expert on Future Network. He completed his PhD in Computer Science in 1996 and his habilitation (HDR) in 2013 from the University of Grenoble (France). He had several research and teaching positions at Grenoble University, European Bioinformatics Institute and Lion Biosciences (Cambridge, U.K.) and Dassault Systems. He joined Orange in 2000 where he had several research expert, project manager, project and program director positions in the area of distributed systems architecture, autonomics, cloud/fog/edge computing and networking. He has been an initiator of Orange activities in autonomic computing, server and network virtualization, cloud/fog/edge computing and networking, digital twins. He is the author of more than 75 refereed articles and has participated in multiple program and organization committees of international conferences in these areas. He has been involved in several collaborative projects and is a regular expert for French (ANR, Inria, Telecom Sud Paris, IMT Atlantique) and European research agencies. Thierry is member of the steering committee of the Inria and Orange joint laboratory IOLab, member of the board of the Edge Intelligence professorship inside the Multidisciplinary Institute in Artificial Intelligence (MIAI), and currently contributes to the Digital Twin Working Group of the French Alliance for the Industry of the Future (AIF). Thierry is one of the creators of the Fractal software component model and more recently the Thing’in digital twin platform. His current research interests include Digital Twins and Edge Intelligence (AI@Edge) for Cyber-Physical Systems.

Title: The case for graph-based multi-actor and cross-vertical digital twin platforms for complex cyber-physical systems – Experience from the Thing’in platform

Abstract: Fuelled by the maturation of technologies such as the Cloud Computing, Artificial Intelligence, and especially the Internet of Things (IoT) which allows for the connexion of the digital world with the physical world (hence the development of Cyber-Physical Systems), Digital Twins are gaining momentum in research and industry, and are reaching many usage domains and markets (e.g. building and cities, transports and logistics, biology and medicine…), far beyond the manufacturing context in which the concept of digital twin emerged. Consequently, we can expect digital twins will come in very different shapes, and will be used for many different usages. Digital Twins platforms, which support the management of digital twins, may tend to cope with this extreme variety by specialising, and targeting narrow vertical markets. A large fragmentation of digital twin technology could hinder however it further development, and perhaps more importantly, could preclude the kind of multi-actor interaction that is required when addressing complex multilevel systems such as buildings, factories, cities or logistics infrastructures. Based on the practical experience of the development of the Thing’in digital twin platform and associated illustrative use cases, this talk makes the case for multi-actor and cross-vertical digital twin platforms, and introduces the technical design choices that can help addressing these requirements.

Olga Fink, ETH Zurich

“Olga Fink has been assistant professor of intelligent maintenance systems at ETH Zürich since October 2018, being awarded the prestigious professorship grant of the Swiss National Science Foundation (SNSF).Olga is also a research affiliate at Massachusetts Institute of Technology and Expert of the Innosuisse in the field of ICT. Olga’s research focuses on Intelligent Maintenance Systems, Data‐Driven Condition‐Based and Predictive Maintenance, Hybrid Approaches Fusing Physical Performance Models and Deep Learning Algorithms, Deep Learning and Decision Support Algorithms for Fault Detection and Diagnostics of Complex Infrastructure and Industrial Assets. Before joining ETH faculty, she was heading the research group “Smart Maintenance” at the Zurich University of Applied Sciences (ZHAW) between 2014 and 2018. Olga received her Ph.D. degree from ETH Zurich with the thesis on “Failure and Degradation Prediction by Artificial Neural Networks: Applications to Railway Systems”, and Diploma degree in industrial engineering from Hamburg University of Technology. She has gained valuable industrial experience as reliability engineer with Stadler Bussnang AG and as reliability and maintenance expert with Pöyry Switzerland Ltd. In 2018, Olga was selected as one of the “Top 100 Women in Business, Switzerland” and in 2019, she was selected as young scientist of the World Economic Forum.”

Title: Algorithms for knowledge and experience transfer between experts and novices for the operation of complex systems

Abstract: “Optimal operation of complex systems requires a substantial experience by skilled operators which may take long to acquire. Such operational experience may be difficult to formalize and consequently transferring such experience from experts to novices can be difficult to establish. The importance of such transfer of experience has been increasing particularly for systems operated under high uncertainty and high requirements on operational performance, such as for example for tunnel boring machines.In tunnel construction projects, delays entail high costs. Thus, tunnel boring machine (TBM) operators aim for high advance rates without compromising safety, a difficult mission in uncertain subterranean environments. Experienced operators are often able to find optimal control parameters based also in uncertain conditions.In this talk, we will present an intelligent decision support system that learns from experienced operators and provides recommendations on the control parameters. The framework is developed in three steps. First, we propose an optimality score to evaluate TBM operation performance, taking into account the advance rate and the working pressure safety. A deep learning model then learns the mapping between the TBM measurements and this optimality score. Finally, in the context of a real application, the model provides incremental recommendations in order to improve the optimality, taking into account the current setting and measurements of the TBM.The proposed approach is evaluated on a real micro-tunneling project and demonstrates great promise for future applications.”

Yoshimasa Masuda, Carnegie Mellon University

Yoshimasa Masuda is currently an instructor, teaching faculty of Executive Professional Education at Carnegie Mellon University, ISR (Institute for Software Research) and Associate Professor (specially appointed) in Graduate school of Media and Governance, Keio University, while working as Senior Manager at Global Business Center in NTT Data Institute of Management Consulting.Yoshimasa Masuda is an internationally expert on Digital Strategy and Enterprise Architecture. Yoshimasa Masuda has 14 years’ experience in enterprise architecture covering technology, application and security in many industries. He earned Ph.D. degree in Keio University. He had lead many global projects with international assignments (Turkey, Shanghai) in IBM. He started up the global enterprise architecture in Global Pharmaceutical company and worked as Sr. IT Director in Softbank group, Robotics in 2019. He completed the Executive Education(MoT) in MIT in 2011, and he has joined Carnegie Mellon University in the US and Australia since 2018. He got “Best Paper Award” in Digital Healthcare areas of KES2019 international conference. His book of “”Enterprise Architecture for Global Companies in a Digital IT Era – AIDAF”” from Springer Nature was rated as the 2nd position in Best New EA books in the first half of 2020, and was ranked among the top 10 EA books of all time by the organization of BookAuthority featured by CNN and Forbes. Furthermore, he got the “Global Achievement Award – Innovative Solutions Award 2021” from worldwide ISACA, by establishing the AIDAF framework. He is also Programme Chair of KES-HCIS international conference, Workshop Chair of IEEE EDOC conference as well as the member of Association for Information Systems and IEEE. He is the editorial review board member for “International Journal of Digital Strategy, Governance, and Business Transformation (IJDSGBT),” IGI Global. His research interests are enterprise architecture with digital IT strategy, digital healthcare, IT management and global leadership. ”

Yoshimasa Masuda is currently an instructor, teaching faculty of Executive Professional Education at Carnegie Mellon University, ISR (Institute for Software Research) and Associate Professor (specially appointed) in Graduate school of Media and Governance, Keio University, while working as Senior Manager at Global Business Center in NTT Data Institute of Management Consulting.Yoshimasa Masuda is an internationally expert on Digital Strategy and Enterprise Architecture. Yoshimasa Masuda has 14 years’ experience in enterprise architecture covering technology, application and security in many industries. He earned Ph.D. degree in Keio University. He had lead many global projects with international assignments (Turkey, Shanghai) in IBM. He started up the global enterprise architecture in Global Pharmaceutical company and worked as Sr. IT Director in Softbank group, Robotics in 2019. He completed the Executive Education(MoT) in MIT in 2011, and he has joined Carnegie Mellon University in the US and Australia since 2018. He got “Best Paper Award” in Digital Healthcare areas of KES2019 international conference. His book of “”Enterprise Architecture for Global Companies in a Digital IT Era – AIDAF”” from Springer Nature was rated as the 2nd position in Best New EA books in the first half of 2020, and was ranked among the top 10 EA books of all time by the organization of BookAuthority featured by CNN and Forbes. Furthermore, he got the “Global Achievement Award – Innovative Solutions Award 2021” from worldwide ISACA, by establishing the AIDAF framework. He is also Programme Chair of KES-HCIS international conference, Workshop Chair of IEEE EDOC conference as well as the member of Association for Information Systems and IEEE. He is the editorial review board member for “International Journal of Digital Strategy, Governance, and Business Transformation (IJDSGBT),” IGI Global. His research interests are enterprise architecture with digital IT strategy, digital healthcare, IT management and global leadership. ”

Title: Digital Enterprise Architecture Approach with IoT Digital Platforms to enable Industry 4.0 in Open Healthcare Platforms 2030

Abstract: Enterprises and societies tend to face crucial challenges, while Indus-try 4.0 becomes important driver in the global manufacturing industry all the more. Industry 4.0 offers a range of many opportunities for companies to enhance the flexibility and efficiency of production processes. Besides, Internet of Things (IoT) provides a strong platform for a number of computer users to connect objects, devices, and people to the Internet for exchanging or sharing of information with each other. IoT is growing rapidly and is expected to adapt to disciplines such as manufacturing, healthcare, agriculture, and robotics, where the new concept of IoT is proposed and shown as Internet of Robotics Things (IoRT). The development of new business models can be promoted with digital platforms and architectures for Industry 4.0. Therefore, products from the healthcare and manufacturing sector can increase in value. The adaptive integrated digital architecture framework (AIDAF) for Industry 4.0 is expected to promote and implement the digital plat-forms and robotics for healthcare and medical communities efficiently. In this briefing, I show that various digital platforms and robotics are designed and evaluated for digital healthcare as for manufacturing industry with Industry 4.0. It can be argued that the design of an open healthcare platform “Open Healthcare Platform 2030 – OHP2030” for medical product design and robotics can be developed with applying the AIDAF. The vision of AIDAF applications for enabling Industry 4.0 in the OHP2030 research initiative is explained and referenced, extended to the context of Society 5.0. The associated challenges and future research directions in this field are also presented.

Chadwick Holmes, Chevron

ChevronChad Holmes has twelve years of experience integrating applied science and engineering skill sets to solve complex problems through primarily R&D and technical service roles at Chevron. Chad earned a Bachelor of Science degree in Earth and Ocean Sciences and Computer Science from Duke University, a PhD in Marine Geophysics from Columbia University, and is currently completing a Master of Science in System Design and Management from MIT.

ChevronChad Holmes has twelve years of experience integrating applied science and engineering skill sets to solve complex problems through primarily R&D and technical service roles at Chevron. Chad earned a Bachelor of Science degree in Earth and Ocean Sciences and Computer Science from Duke University, a PhD in Marine Geophysics from Columbia University, and is currently completing a Master of Science in System Design and Management from MIT.

Joshua Fant, US Coast Guard

Joshua W. Fant Commanding Officer Asset Project Office Baltimore | U.S. Coast Guard. Josh Fant is a career civil engineering and acquisition project officer with twenty-three years of experience leading innovative organizations to deliver construction, logistics and acquisition assets for the United States Coast Guard. Josh currently develops logistics and supply chain packages for the Coast Guard’s newly acquired cutters. Josh earned a Bachelor’s of Science degree from the United States Coast Guard Academy in Marine and Environmental Science, a Master’s of Engineering in Ocean Engineering from Texas A&M University and a Master’s of Science in Project Management from George Washington University. He is currently completing a Master’s of Science in Engineering and Management from MIT’s System Design and Management program.

Joshua W. Fant Commanding Officer Asset Project Office Baltimore | U.S. Coast Guard. Josh Fant is a career civil engineering and acquisition project officer with twenty-three years of experience leading innovative organizations to deliver construction, logistics and acquisition assets for the United States Coast Guard. Josh currently develops logistics and supply chain packages for the Coast Guard’s newly acquired cutters. Josh earned a Bachelor’s of Science degree from the United States Coast Guard Academy in Marine and Environmental Science, a Master’s of Engineering in Ocean Engineering from Texas A&M University and a Master’s of Science in Project Management from George Washington University. He is currently completing a Master’s of Science in Engineering and Management from MIT’s System Design and Management program.

Eric Young, US Navy

Eric Young Submarine Officer, United States NavyDuring his first five years of naval service, Eric Young applied engineering principles to help test and deliver America’s newest nuclear submarines. Eric earned Bachelor of Science degrees in Computer Science and Information Technology from the United States Naval Academy and currently studies Naval Engineering and System Design and Management at MIT.

Eric Young Submarine Officer, United States NavyDuring his first five years of naval service, Eric Young applied engineering principles to help test and deliver America’s newest nuclear submarines. Eric earned Bachelor of Science degrees in Computer Science and Information Technology from the United States Naval Academy and currently studies Naval Engineering and System Design and Management at MIT.

Title: A Digital Ocean framework for improved ship utilization and design

Abstract: “The unceasing demand for global commerce requires the maritime industry to spend significant time maintaining and certifying ships to continue operations. Much of the uncertainty in this process comes from inspecting and repairing ship hulls damaged by flexing and strain imposed by ocean waves. Over time, this strain fatigues structural elements, initiating cracking and eventual failure. The maritime industry presently identifies strain damage by visual inspections conducted every few years. While these inspections demand high standards, they subject all ships to the same procedure lacking sufficient detail for individual vessel lifespan predictions. Erring on the side of safety, operators may retire ships much earlier than necessary, particularly those that experienced a relatively low strain history.We propose a different approach to determining the useful life of marine vessels. This Digital Ocean framework combines data storage, information processing, and digital modeling to inform the maritime sector about ship structural fatigue levels. The system pairs individual vessel agents, each collecting wave and strain data, with a ship-specific finite element processing system that characterizes fatigue damage. In addition, the system relates calculated damage with wave data to determine how transit history impacted the structural health of a ship. Finally, this combined wave-fatigue data is used to predict the damage future ships may incur when traveling different ocean routes. Digital Ocean fatigue monitoring and prediction tools would benefit shipping industry stakeholders (e.g., ship owners, shipping, insurance companies) by providing the day-to-day ship health information necessary for safe and timely voyages. Route-correlated strain and prediction forecasts allow shipping companies to maximize profitability by choosing low-fatigue routes that extend the service life of their fleet. And the system would provide data to researchers, influence future ship design methodologies, and support data science applications, ultimately helping realize the sustainable shipping and profitability goals outlined by Maritime 4.0.”

Sixiong Peng, University of Tokyo

Sixiong Peng is a second-year student at Graduate School of Frontier Science in University of Tokyo and pursuing a doctoral degree in Human and Engineered Environmental Studies. He has worked for Japan Social Innovation Center since 2019, where he participates, designs, facilitates and researches idea generation workshops. This experience led him to start research on idea generation in teams. His interests include: thinking process for idea generation, effective teamwork in innovation projects and support tools for idea generation. After investigating the iteration process of idea generation in his past research, he currently focuses on teamwork analysis using audiovisual data in remote workshops.

Sixiong Peng is a second-year student at Graduate School of Frontier Science in University of Tokyo and pursuing a doctoral degree in Human and Engineered Environmental Studies. He has worked for Japan Social Innovation Center since 2019, where he participates, designs, facilitates and researches idea generation workshops. This experience led him to start research on idea generation in teams. His interests include: thinking process for idea generation, effective teamwork in innovation projects and support tools for idea generation. After investigating the iteration process of idea generation in his past research, he currently focuses on teamwork analysis using audiovisual data in remote workshops.

Title: Teamwork Visualization using audiovisual data: case of remote innovation workshop

Abstract: Outbreak of COVID-19 has triggered a rapid spread of remote work, which has the potential to increase the diversity of employees and the creativity of teams within an organization while making it difficult for teams to collaborate. Hence, how to support teamwork in a remote environment has become an important issue for companies nowadays. For understanding the current status of teamwork and supporting it, utilizing behavioral data generated through remote communication is promising. Compared to questionnaires and interviews which are used in conventional teamwork research, behavioral data is less intrusive to obtain, can be utilized in real time, and provides more objective information. This presentation particularly focuses on synchronous communication of a small team in a context of idea generation and discusses how teamwork can be visualized from audiovisual data which can be obtained from video conferencing apps. We use recordings of several idea generation workshops which were held remotely as samples. We firstly explain several potential indicators of teamwork such as variance of turn-taking, number of utterances, and gap length between utterances, and introduce a diagram that visualizes a time-to-time change of teamwork by combining these indicators. We then discuss several aspects of teamwork represented by the diagram. Specifically, we focus on “hot state” in which teams are discussing evenly and actively. Such a state where every member engages in discussion is expected to happen when teams have shared understanding of discussion topics and facilitate knowledge creation. Finally, we discuss future research and propose potential usage of the diagram in business and research context.

Benjamin Baumann, John Deere as Digital Product Manager for Operation Technologies and Automation

Benjamin Baumann is currently working at John Deere as Digital Product Manager for Operation Technologies and Automation. His responsibility includes amongst others the development, deployment, and support of Deere’s Manufacturing IoT Platform to ensure seamless connectivity from shop floor device to cloud (and back). Benjamin has 11 years of experience across various areas in manufacturing, such as manufacturing engineering, operations, automation, and digitalization. He holds a diploma in mechanical engineering and a PhD in Production Engineering, both from the RWTH Aachen University, Germany.

Benjamin Baumann is currently working at John Deere as Digital Product Manager for Operation Technologies and Automation. His responsibility includes amongst others the development, deployment, and support of Deere’s Manufacturing IoT Platform to ensure seamless connectivity from shop floor device to cloud (and back). Benjamin has 11 years of experience across various areas in manufacturing, such as manufacturing engineering, operations, automation, and digitalization. He holds a diploma in mechanical engineering and a PhD in Production Engineering, both from the RWTH Aachen University, Germany.

Title: Manufacturing IoT – Value Creation through Guided Democratization

Abstract: Three out of four Industrial IoT implementations fail. While the reasons for this might be manifold, it comes down to a misfit between the following aspects: the issue to be solved, the chosen solution, the people and their skillset to support and maintain the new systems, as well as the legacy infrastructure.

To overcome this challenge all four edges of this quadrupole need to come closer together: the new customized solutions need to solve an actual problem while the new technology allows an evolution away from its legacy infrastructure without disrupting critical (manufacturing) processes. This can only be accomplished if the used tools allow short, iterative innovation cycles and the end users on the shopfloor are not only included but actually becoming solution developers: Democratization of IT is the new buzz word! This session will share insights how John Deere Manufacturing Technologies deals with this topic and why we think that in this context Democratization of IT needs a guiding hand.

Eric C. Cosman, the founder and Principal Consultant at OIT Concepts, LLC

Eric C. Cosman is the founder and Principal Consultant at OIT Concepts, LLC. He provides consulting and advisory services to suppliers, professional associations, and asset owners, focusing on management of information technology solutions in Process Automation, Operations, and Engineering. This includes providing guidance on the definition and leadership of collaborative teams between IT and OT organizations. With over 35 years of experience in the process industries, Eric has held positions in process engineering, process systems software development, telecommunications, IT operations, automation architecture, and consulting. His assignments have included system architecture definition and design, project management, technology life cycle management, and integration planning for manufacturing focused IT systems. This includes having worked closely with virtually all major suppliers of process automation systems and technology. Eric contributes to and has held leadership positions in various standards committees and industry focus groups and is a member of Control Magazine’s Process Automation Hall of Fame. He has been a contributor to the work of several standards committees with the International Society of Automation (ISA), and has served as their vice president of standards and practices, and was the ISA President for 2020. Eric has been a leader in the development of standards and practices for industrial control systems security since 2002. He was a founding member of a Chemical Sector Cyber Security Program team focused on industrial control systems cyber security and was one of the authors of the Chemical Sector Cyber Security strategy for the U.S. He is also a founding member and currently serves as the co-chair of the ISA99 committee on industrial automation and control systems (IACS) security. Eric is a frequent conference speaker and has written articles and columns for a variety of industry magazines.

Eric C. Cosman is the founder and Principal Consultant at OIT Concepts, LLC. He provides consulting and advisory services to suppliers, professional associations, and asset owners, focusing on management of information technology solutions in Process Automation, Operations, and Engineering. This includes providing guidance on the definition and leadership of collaborative teams between IT and OT organizations. With over 35 years of experience in the process industries, Eric has held positions in process engineering, process systems software development, telecommunications, IT operations, automation architecture, and consulting. His assignments have included system architecture definition and design, project management, technology life cycle management, and integration planning for manufacturing focused IT systems. This includes having worked closely with virtually all major suppliers of process automation systems and technology. Eric contributes to and has held leadership positions in various standards committees and industry focus groups and is a member of Control Magazine’s Process Automation Hall of Fame. He has been a contributor to the work of several standards committees with the International Society of Automation (ISA), and has served as their vice president of standards and practices, and was the ISA President for 2020. Eric has been a leader in the development of standards and practices for industrial control systems security since 2002. He was a founding member of a Chemical Sector Cyber Security Program team focused on industrial control systems cyber security and was one of the authors of the Chemical Sector Cyber Security strategy for the U.S. He is also a founding member and currently serves as the co-chair of the ISA99 committee on industrial automation and control systems (IACS) security. Eric is a frequent conference speaker and has written articles and columns for a variety of industry magazines.

Title: Automation at the Core of Digital Transformation

Abstract: Wikipedia defines Digital Transformation as “the adoption of digital technology to transform services or businesses, through replacing non-digital or manual processes with digital processes or replacing older digital technology with newer digital technology.” While many may consider Digital Transformation to be a recent trend or phenomenon, automation professionals have been doing this in plant or production operations for many decades, since the first replacement of manual or analog controls with their digital successors. The continued pursuit of digital transformation presents a wide range of opportunities for the automation professional. While it is certainly true that state of the art technologies provide capabilities that may not have been available previously, there are certain concepts and principles at the core of accepted practices that are independent of specific technologies. These include an absolute commitment to process safety, pursuit of improved asset performance and optimization of processes and resource consumption. Ultimately, the goal is to operate production and manufacturing operations as close as possible to the limits imposed by economics and the laws of physics. Understanding the potential of new and transformative technologies is very important, but an appreciation of proven principles and practices is critical if their application is to be successful in the long term. It is a blending of new enabling technology and a solid grounding in engineering design that will create lasting results. This is best accomplished through effective collaboration between several disciplines. This presentation explores what is required for such a collaboration, highlighting specific examples, and drawing parallels to previous practices.

Akira Ishizaka, the Graduate School of System Design and Management, Keio University

Akira Ishizaka is a researcher at the Graduate School of System Design and Management, Keio University. Akira has been working in production engineering and safety management of plants for about ten years and has been engaging in research of model-based systems engineering for the critical infrastructure domain. At the same time, Akira is participating as a researcher in the Digital Architecture Design Center (DADC), Japan’s public organization established in 2020. Akira earned a Bachelor of Engineering degree from Chiba University in Urban Environment Systems and a Master of System Engineering from Keio University. He is a qualified INCOSE, Associate Systems Engineering Professional (ASEP).

Akira Ishizaka is a researcher at the Graduate School of System Design and Management, Keio University. Akira has been working in production engineering and safety management of plants for about ten years and has been engaging in research of model-based systems engineering for the critical infrastructure domain. At the same time, Akira is participating as a researcher in the Digital Architecture Design Center (DADC), Japan’s public organization established in 2020. Akira earned a Bachelor of Engineering degree from Chiba University in Urban Environment Systems and a Master of System Engineering from Keio University. He is a qualified INCOSE, Associate Systems Engineering Professional (ASEP).

Title: An Architecture Description of Resilience-Oriented Engineering Process Toward Smart Chemical Industries

Abstract: The Japanese government has been advocating a “Smart Safety” initiative to actively adopt AI, IoT, and Big Data in plant maintenance as the country’s oil refining and chemical industries face aging equipment and the mass retirement of veteran operators. However, while chemical plants are becoming “smarter,” Cyber-Physical Systems (CPS) for advanced collaboration beyond the bounds of companies and government agencies have been discussed for about eight years but have not been realized in Japan. CPS are integrations of computation with physical processes. Therefore, to realize CPS, it is necessary to understand a process that system-of-interest has deeply. However, a common understanding of the engineering process among stakeholders is not easy because the chemical industry and regulatory authorities have various agencies, and they have their own purposes. Simultaneously, since the chemical industry deals with large amounts of flammable liquids and high-pressure gases, strong coordination with stakeholders is required throughout their lifecycle. The chemical industry and its regulatory bodies should follow the resilience principle, which entails anticipating a major disaster in physical or cyber space, dealing with the disaster’s disruption as it occurs, and adaptively evolving socio-technical systems such as facilities, organizations, laws, and mandated drills, etc. Researching solutions through models that abstract from concrete factors is one effective way for systems engineers or administrative officers to make desirable decisions in complex situations. In this presentation, we will discuss the architecture that characterizes the resilience-oriented engineering process through the lifecycle of the chemical industry to realize a “Smart Chemical Industry.” The architecture is described by the Integration Definition 0 (IDEF0), and the process of adapting to safety regulations and actual disasters in the Japanese chemical industry is shown in the case studies. The architecture, which captures the life cycle of the chemical industry, is expected to facilitate collaboration among stakeholders and encourage the realization of the CPS.

Gretchen Myers, Chevron, Houston, TX USA

Gretchen leads an IT/OT architecture function at Chevron, responsible for developing standardized, scalable IT capabilities for OT; defining reference architectures and guardrails to deploy emerging technologies and building the foundation for Chevron’s digital transformation. During her 25+ years working in IT strategy/operations, cybersecurity and information risk, she has published both IS/IT and risk management strategies, built new IT service delivery and security organizations, and successfully delivered large-scale enterprise programs and projects for global companies.

Gretchen leads an IT/OT architecture function at Chevron, responsible for developing standardized, scalable IT capabilities for OT; defining reference architectures and guardrails to deploy emerging technologies and building the foundation for Chevron’s digital transformation. During her 25+ years working in IT strategy/operations, cybersecurity and information risk, she has published both IS/IT and risk management strategies, built new IT service delivery and security organizations, and successfully delivered large-scale enterprise programs and projects for global companies.

She is a recognized thought leader within Chevron having led different work in key enterprise initiatives including author of Chevron’s Security by Design digital imperative; Cybersecurity Architect for 2017 -2018 Enterprise Cloud Program; Cloud Security Lead in 2015 – 2017 Cybersecurity Acceleration Program, delivering commitments for Cloud Discovery/Data Control; and most recently, launching multiple R&D initiatives for IIoT to an internal IT/OT platform service hosted in Azure.

She has held the Certified Information Systems Security Professional (CISSP) certification for over 16 years.

Title: Teaming on the Edge: Cloud and IoT Integration Moving at the Speed of Business

Abstract: Chevron’s digital transformation required cross-functional teams to come together in new ways to apply the Internet of Things (IoT), Cloud and artificial intelligence and machine learning (AI/ML) technologies to existing and new facilities. The evolution of informal relationships into new organizational models has streamlined the discussions around how to apply, and then scale, these technologies.

For many years, research analysts’ teams were able to agilely respond to requests from subject matter experts to build targeted prototypes solving unique problems for field operations. However, scaling the deployment of these prototypes has taken much longer than anticipated not just because of technology challenges, but also recognizing new operating models and partnerships between different functions are required for success. This session will present an overview of Chevron’s engineering, IT and operation stakeholders are meeting the challenge to deploy and secure next-gen cloud & IoT architectures. Key objectives have included

- Building an innovation culture to re-orient engineering and IT resources to agile mindsets

- Re-imagining the IT operating model to better partner with central engineering and local operations

- Harnessing standardization and automation to build consistent and repeatable outcomes

- Articulating noteworthy business outcomes to gain—and keep—momentum